1 .顎粉砕ステーションはユニークなモジュールを採用している。いいえ、溶接フレーム構造。

2 .大きな傾斜角破砕空洞とより良いこう合角,生産性は25 %増加した。

3 .吐出口の大きさの油圧調整。

4 .給餌システムは、顧客の現場作業条件に応じてカスタマイズすることができます。

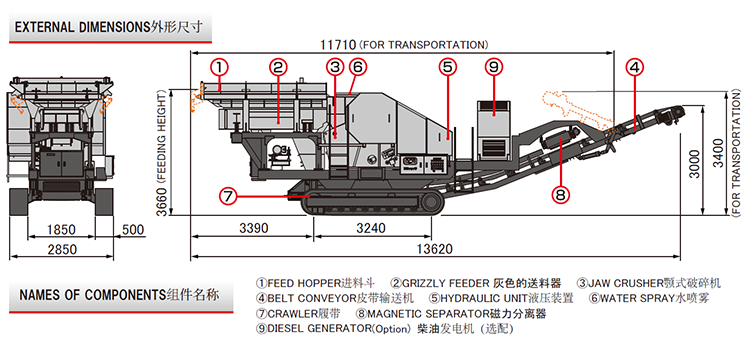

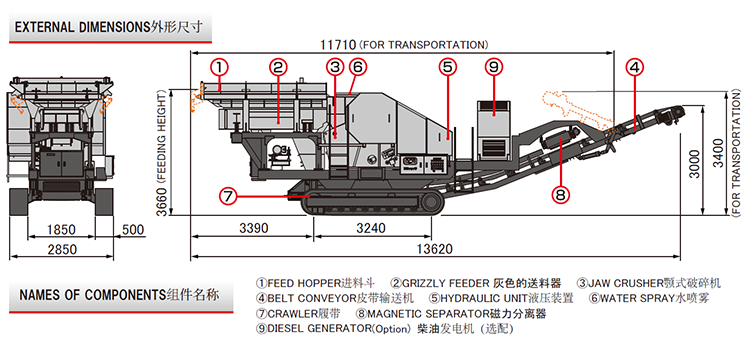

5 .コンパクトなデザインは、輸送と輸送に便利です。

6 .無線遠隔操作は機器オペレータを減らすことができるコンポーネントモデル産総研

| Component | Model | MC-60J | MC106J | MC113J | Component | Model | MC-60J | MC-106J | MC-113J |

|

Feeding device

|

Feeding capacity(t/h) | 100 | 450 | 450 | Tail belt conveyor | Stack height (mm) | 2000 | 2300 | 2300 |

| Max.feeding(mm) | 380 | 700 | 750 | LengthxWidth(mm) | 2580xB500 | 3600xB500 | 3600xB500 | ||

| Feeding height(mm) | 3000 | 4100 | 4100 | Power(kw) | 3 | 3 | 3 | ||

| Hopper volume(m3) | 3 | 5 | 5 | Whole machine | Walking engine power (kw) | 70 | 90 | 90 | |

|

Vibrating feeder

|

LengthxWidth(mm) | 3100 x 600 | 4000x1040 | 4000x1040 | Total Weight(t) | 15 | 44 | 45 | |

| Power(kw) | 2.2x2 | 3.7x2 | 3.7x2 | Work efficiency(t/h) | 30-80 | 130-450 | 130-450 | ||

| Crusher | Special jaw crusher | C60 | C106 | C113 |

Transport size LengthxWidthx Height(m) |

13x2.7x3 | 16x3.3x3.7 | 16x3.3x3.7 | |

| Length and width of crusher mouth(mm) | 420 x 650 | 1060 x 700 | 750x1130 | Total power(kw) | 50 | 135 | 135 | ||

| Max. feed(mm) | 380 | 700 | 750 |

Remarks: 1.The efficiency of the crusher is related to the hardness of the stone, the particle size of the feed, and the particle size of the discharge. 2. Standard configuration: tailing belt, manual control, wireless remote control 3. Optional: Return material system, foldable conveyor belt, iron remover, dust removal spray system, belt cover. 4. Specs and dimensions of this machine are subject to the actual product. They might be changed without any prior notice for the purpose of improvement. |

|||||

| Discharge size(mm) | 30-100 | 70-200 | 70-200 | ||||||

| Crusher weight(t) | 6.5 | 18 | 19 | ||||||

| Power(kw) | 37 | 110 | 110 | ||||||

| Main belt conveyor | Stack height(mm) | 3000 | 3200 | 3200 | |||||

| LengthxWidth(mm) | 8000 xB650 | 13000 xB1200 | 13000xB1200 | ||||||

| Power(kw) | 5.5 | 15 | 15 |

|

|||||